| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : HAIJIA

Model Number : HJF360

Certification : CE ISO9001

Place of Origin : CHINA

MOQ : 1 set

Price : Negotiation

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 100 Set/Sets per Month

Delivery Time : 20-30days

Packaging Details : Standard Export Package for Injection Machine

Voltage : Customed Avaiable

Used for : Plasic Products

Motor : servo & standard & variable pump

Keyword : energy saving

Warranty : 18 months

Plastic type : Thermoplastic

1. Treatment of plastics

Because PET macromolecule contains lipid group, it has certain hydrophilicity. Particles are sensitive to water at high temperature. When the moisture content exceeds the limit, the molecular weight of PET decreases and the products become colored and brittle.

Therefore, before processing, the material must be dried, its drying temperature is 150 C, more than 4 hours; generally 170 C, 3-4 hours. It can be used to check whether the material is completely dry. The proportion of recycled PET bottle blank should not exceed 25%, and the recycled PET bottle blank should be thoroughly dried.

2. Selection of Injection Molding Machine

Because of the short time of stabilization after melting point and the high melting point of PET, the injection system with more temperature control section and less self-friction heat generation during plasticization should be selected, and the actual weight of the product (water-containing orifice) should not be less than 2/3 of the injection volume of the machine.

3. Mould and gate design

PET bottle embryo is usually formed by hot runner mould. It is better to have a heat insulation plate between the mould and the injection machine template. The thickness of the heat insulation plate is about 12 mm, and the heat insulation plate must be able to withstand high pressure. Exhaust must be sufficient to avoid local overheating or fragmentation, but the exhaust outlet depth should not exceed 0.03mm, otherwise it is easy to produce flash.

|

|

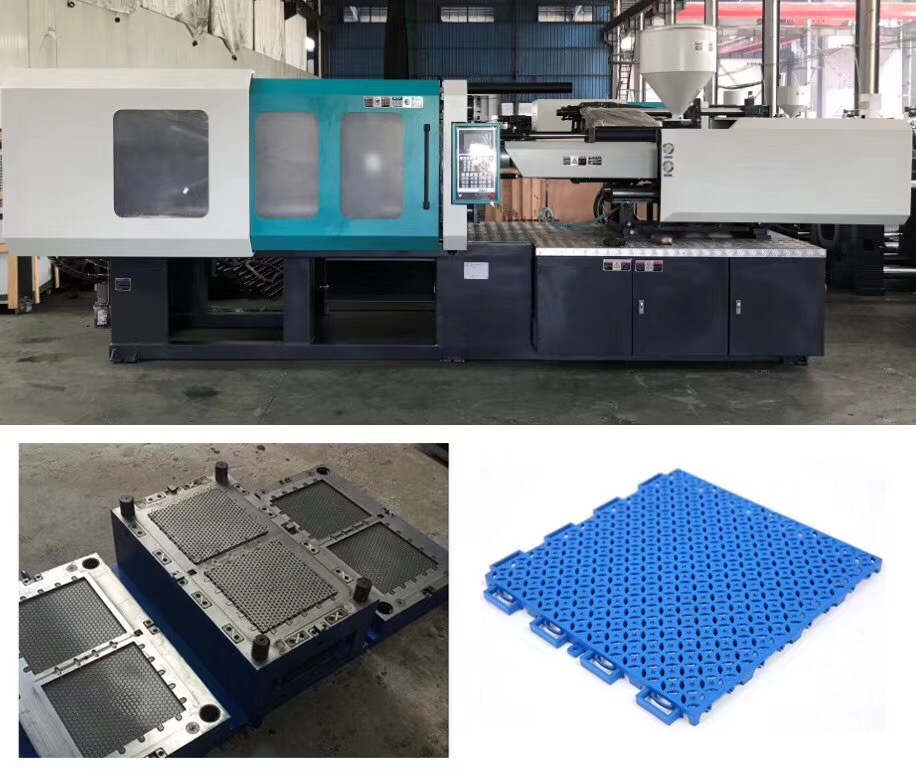

plastic mats for floor making Injection Molding Machine servo injection moulding machine Images |